Liquid Silicone Rubber is a low viscosity and high purity thermoset elastomer maintaining mechanical properties over a wide range of temperatures (from -50°C to 250°C). This heat-cured elastomer provides excellent optical clarity, durability and design freedom. This innovative transparent material serves diverse applications such as medical, automotive, dairy, food processing, semiconductor and consumer products. Hensim designs and builds our tooling in-house to support this service.

Liquid injection molding (LIM), or liquid silicone rubber (LSR) molding, uses highly viscous liquid in two parts that are blended with a platinum catalyst to accelerate cure times. LIM or LSR molding is perfect for high-volume manufacturing because of the quicker cure rate, and since it is a closed molding method, uncured raw material is never in contact with workers. This technique is ideal for high-purity applications.

The components Hensim aims to produce are the result of your and our designers' imagination plus the quest for innovative solutions of our toolmakers and process engineers.

Many companies in the healthcare, automotive, electronics, and hardware industries already make use of LSR, and you could too.

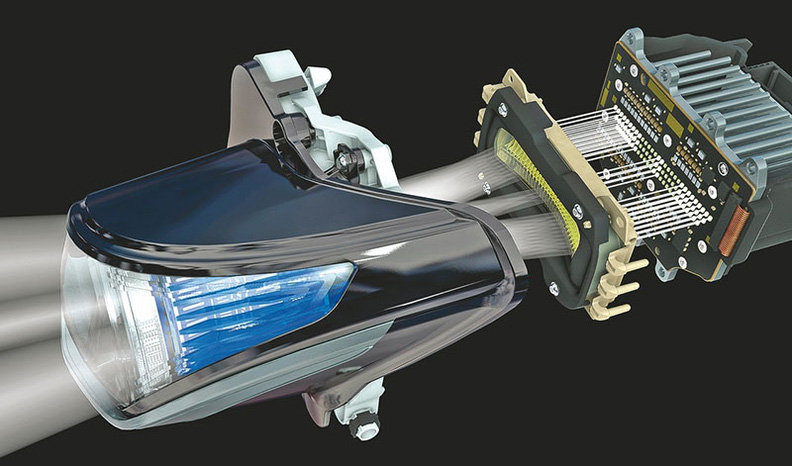

Automotive

Parts made of silicone elastomers are used in automobiles in large quantities and many varieties, primarily as cable support sleeves for all cable conduits through bodywork panels, but also as folding bellows and damping elements.

Medical components

Silicone is flexible and bio-compatible, therefore suitable for many applications in medical technology and bio science. The portfolio includes respiratory masks, sealing elements for blood filters, as well as prosthetic components and even artificial hearts. Thanks to their high heat resistance, silicone components can be sterilized.

Household/lifestyle/Consumer Goods

Thanks to its olfactory and taste neutrality, LSR is ideal for making consumer goods such as wearable devices, cookware, cosmetics applicators, brushes, Baby toys, feeding products and closures for drinking bottles. Due to their variable properties in many areas, e.g. electrically conductive or insulating, high heat resistance without loss of stability, silicone elastomer parts are an excellent solution for combined loads and functions.

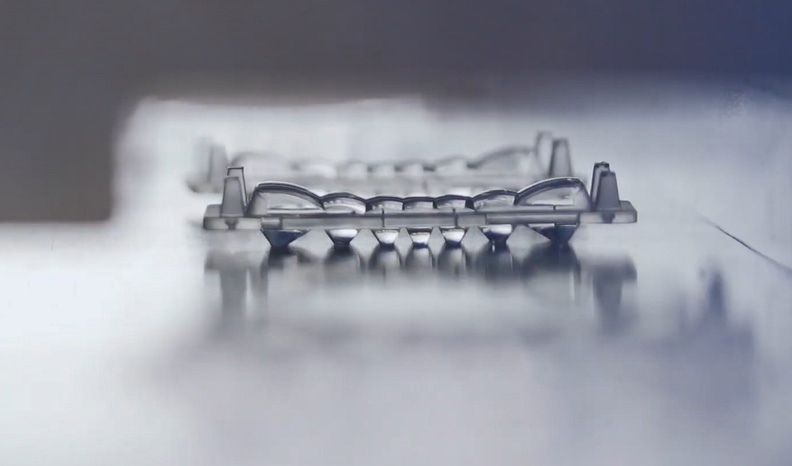

Optical parts

Thanks to their excellent optical attributes and heat resistance, silicones are used in lens production and lighting technology.

Electrical

Cable insulators, Lightbulb shells and shades