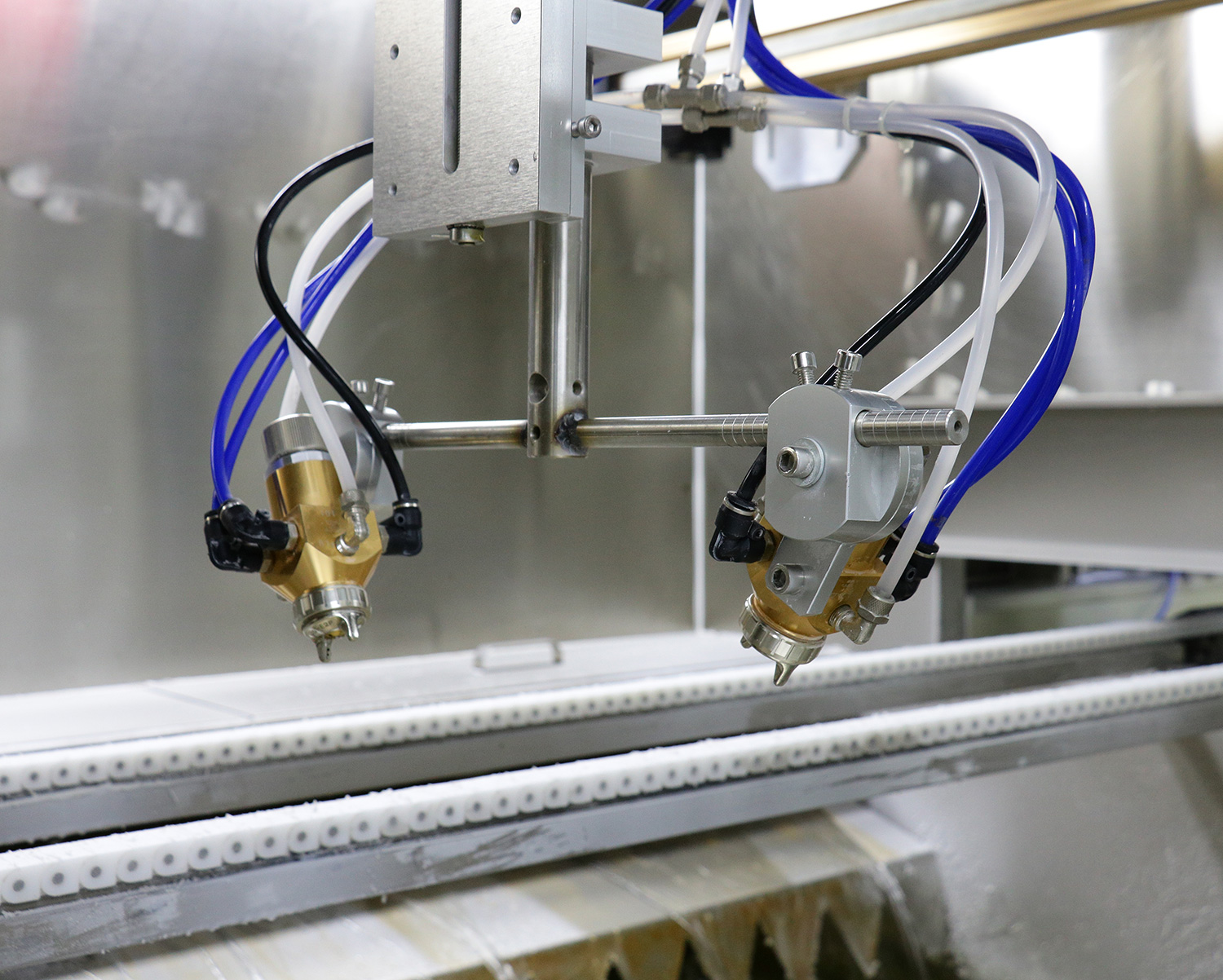

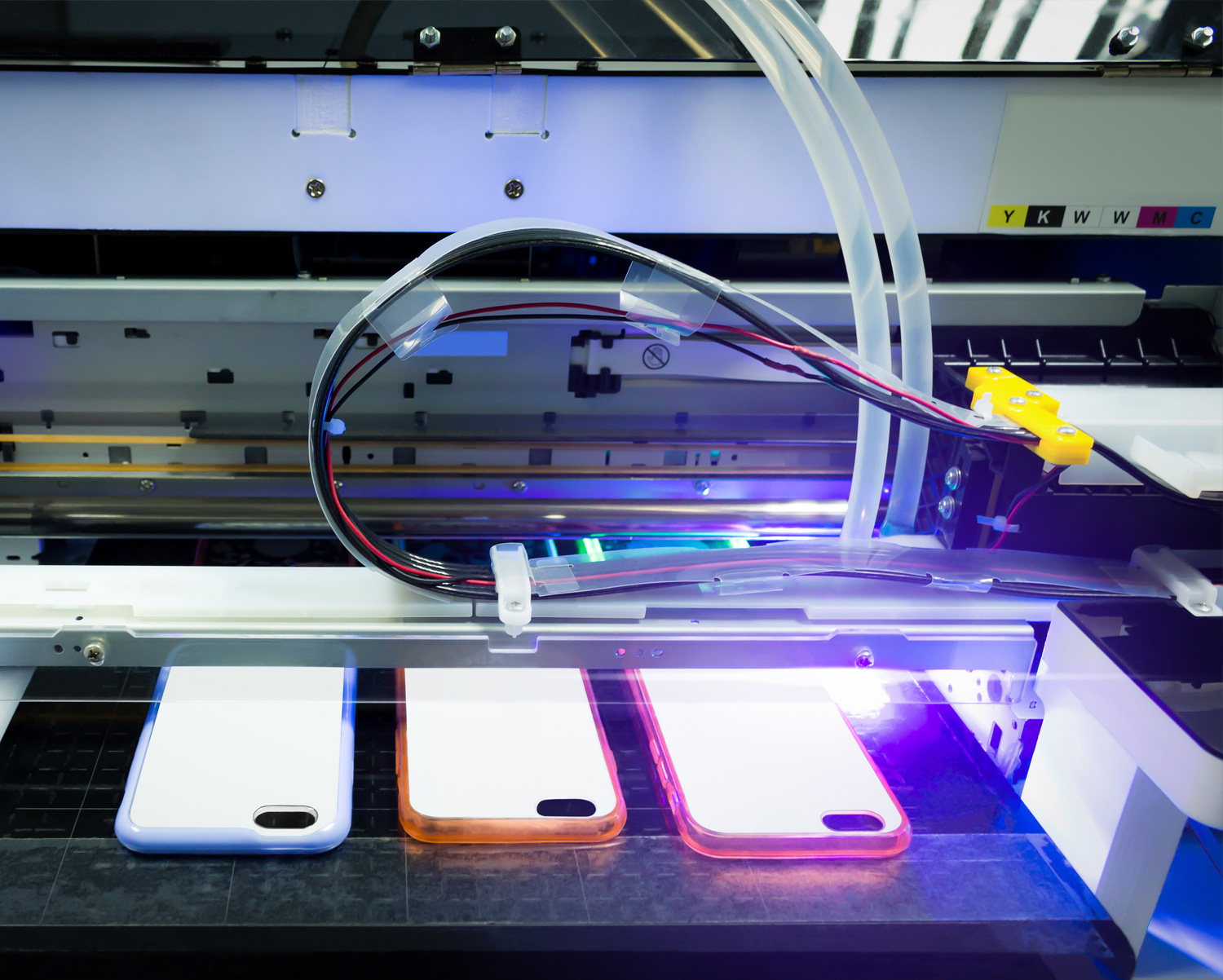

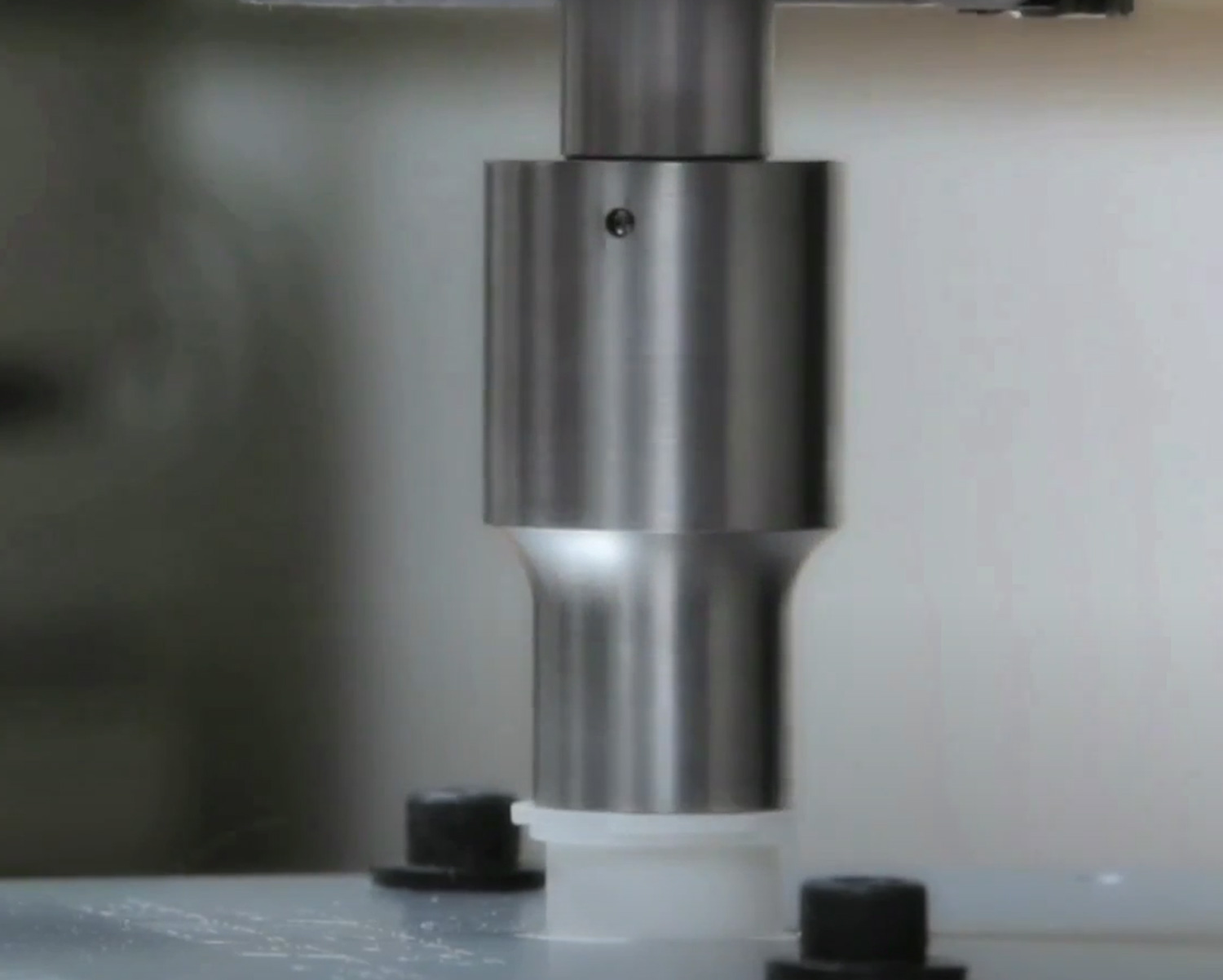

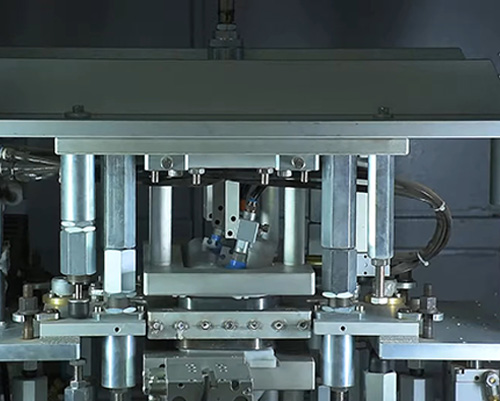

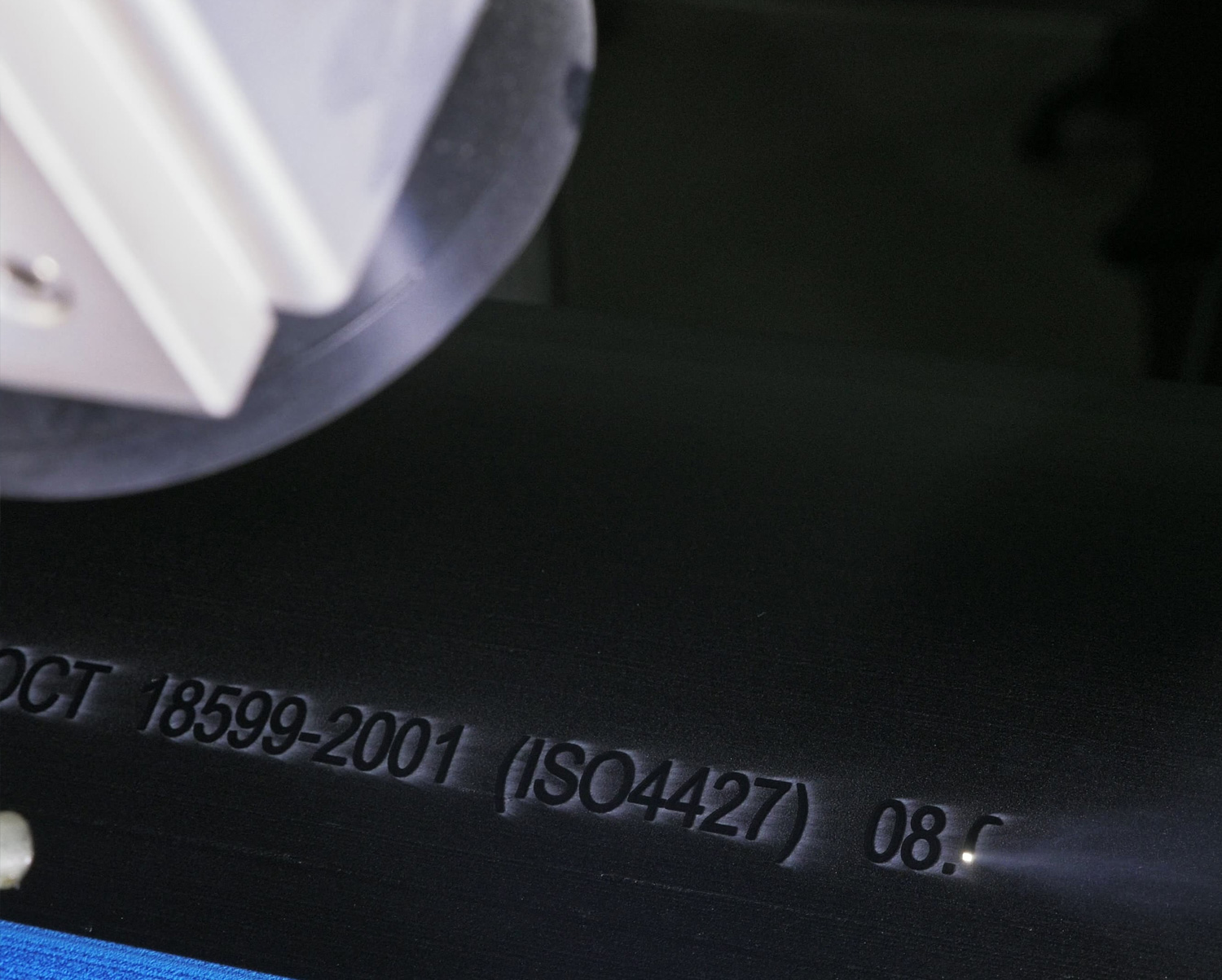

Hensim’s factory is equipped with the latest injection molding technologies and machineries from renown manufacturers. All the processes are automated to a great extend and optimized for consistent production quality and maximal efficiency.

With more than 10 years of experience in various industries, we offer an extremely solid foundation for successful production solutions. Within our operations, all production processes are seamlessly coordinated, allowing us to provide a high-quality plastic injection molding process in a cost-effective manner.

Locations: Huizhou, Guang Dong province, China. State of the art equipment with ongoing investments.

Tooling Capacity: up to 66 injection mold tooling sets per month. Injection molding production: 500,000 to 5000,000 pieces per month.